fiber optic cable color code chart pdf

Fiber Optic Cable Color Code Chart PDFs⁚ A Comprehensive Guide

This guide explores the essential aspects of fiber optic cable color coding, using PDF charts as a primary reference. We’ll delve into standards, variations across manufacturers, and practical applications for field identification and troubleshooting. Downloadable resources and industry examples are included.

Introduction to Fiber Optic Cable Color Codes

Consistent identification of individual fibers within a cable is crucial for efficient installation, maintenance, and troubleshooting in fiber optic networks. Color coding provides a standardized, visual method for this identification. This system uses a sequence of colors to distinguish each fiber, simplifying the process of tracing and connecting fibers. The most prevalent standard, TIA-598-C, employs a 12-color sequence, often memorized using mnemonics. However, variations exist due to manufacturer-specific practices and the need to accommodate cables with more than 12 fibers; Understanding these color codes is essential for anyone working with fiber optic cables, from installers and technicians to network engineers and designers. Proper color code interpretation ensures that fibers are correctly identified and connected, avoiding costly errors and downtime. This introduction sets the stage for a deeper exploration of the intricacies of fiber optic color coding schemes.

TIA-598-C Standard and its Mnemonic

The Telecommunications Industry Association (TIA) standard TIA-598-C defines a widely adopted 12-color code sequence for identifying individual optical fibers within a cable. This standard ensures uniformity and simplifies the process of fiber identification across various applications. The sequence begins with blue, followed by orange, green, brown, slate, white, red, black, yellow, violet, rose, and aqua. To aid memorization, a common mnemonic is used⁚ “Bad Boys Rape Our Young Girls But Violet Gives Willingly.” Each word’s first letter corresponds to a color in the sequence. This mnemonic, while informal, helps technicians quickly recall the color order. While TIA-598-C is a cornerstone of fiber optic cable identification, it’s crucial to remember that this is a standard, not a universally enforced rule. Manufacturers may use variations, especially for cables exceeding 12 fibers. Understanding the TIA-598-C standard is fundamental but needs to be complemented by awareness of potential deviations.

Color Codes for Different Fiber Types (Single-Mode, Multi-Mode)

While the TIA-598-C standard primarily focuses on the sequence of colors used to identify individual fibers within a cable, it doesn’t inherently dictate color codes based on fiber type (single-mode or multi-mode). The color coding system primarily addresses the physical identification of individual fibers within the cable structure, not their optical properties. The distinction between single-mode and multi-mode fibers is determined by their core diameter and the type of light propagation they support, and this information is typically found in the cable specifications rather than directly indicated by color. Therefore, a color code chart will not specifically differentiate between single-mode and multi-mode fibers through color alone. Instead, it’s essential to consult the cable’s accompanying documentation or markings for this crucial information. The color code is primarily for physical organization and identification within a cable, not for differentiating fiber types.

Beyond the 12-Color Sequence⁚ Handling Larger Fiber Counts

The standard TIA-598-C 12-color sequence forms the foundation of fiber optic cable color coding, but many applications demand more than 12 fibers. To accommodate higher fiber counts, manufacturers employ various strategies, often involving repetition of the 12-color sequence alongside additional identifiers. A common method is to repeat the basic sequence, differentiating repeated colors using secondary markings like stripes or tracers. For example, fiber 13 might be identical in primary color to fiber 1 but include a black stripe for clear distinction. Another approach involves using a combination of colors and numerical markings printed directly onto the fiber or its protective jacket. This ensures unambiguous identification, even with hundreds of fibers. The specific method employed can depend on the cable construction (ribbon, loose tube, etc.) and the manufacturer’s specifications. Consulting a detailed color code chart specific to the cable in question is crucial for accurate identification in these higher-fiber-count scenarios. These charts often provide a legend translating the combined color and stripe/number codes to the specific fiber number.

Color Coding in Different Cable Constructions (Ribbons, Loose Tubes)

Fiber optic cables come in various constructions, each impacting how color coding is applied. Ribbon cables, featuring multiple fibers bundled together in a flat ribbon, often utilize a repeating color sequence across the ribbon’s width. Each fiber within a ribbon might have a unique color, or a combination of color and stripe, to distinguish it from others. Individual ribbons might also be color-coded for further identification within a larger cable assembly. Loose tube cables, which contain fibers housed within a loose tube filled with a protective gel, typically employ color coding on the loose tubes themselves. These tubes are bundled together, and each tube might contain multiple fibers with their own internal color coding scheme. The color coding of the outer tubes further differentiates the groups of fibers. Understanding the cable’s construction is vital for proper interpretation of the color code. A PDF chart specific to the cable type will clearly indicate whether colors refer to individual fibers, groups of fibers within a ribbon or loose tube, or the tubes themselves. Manufacturer documentation is invaluable in deciphering these complexities, allowing for accurate fiber identification and termination.

Manufacturer-Specific Variations and Customizations

While standards like TIA-598-C provide a common framework, manufacturers may introduce variations or customizations to their fiber optic cable color coding schemes. These deviations can stem from various factors, including legacy systems, specific customer requirements, and the need to accommodate larger fiber counts beyond the standard 12-color sequence. Some manufacturers might employ slightly different color shades or introduce additional markings like stripes or tracers to enhance identification within their product lines. Others may use proprietary color codes entirely, especially for specialized applications or custom cable designs. Therefore, relying solely on generic color code charts can be misleading. Always consult the manufacturer’s specifications or data sheets accompanying the specific cable in question. These documents will provide the definitive color code chart and any relevant explanations of unique markings or deviations from standard practices. Ignoring manufacturer-specific details can lead to misidentification, potentially causing costly errors during installation, testing, or maintenance. This highlights the crucial role of precise documentation and the necessity of referring to the provided manufacturer’s documentation for accurate interpretation.

Identifying Fibers Using Stripes and Tracers

When the standard 12-color sequence is insufficient for identifying individual fibers within a cable, manufacturers often employ stripes or tracers to expand the number of distinguishable fibers. These additional markings are typically applied to the base color, creating a unique visual identifier for each fiber beyond the initial 12. A common method involves using black stripes or tracers on the primary color. For instance, a fiber might be identified as “Orange with a black tracer,” clearly distinguishing it from a plain orange fiber. The exact implementation of stripes and tracers can vary among manufacturers, and the specific pattern may follow a defined system or be arbitrary, depending on the manufacturer’s internal coding scheme. Therefore, interpreting these markings requires careful reference to the accompanying documentation, which includes the manufacturer’s specific color code chart. This chart will show the complete legend, clarifying the meaning of each stripe or tracer combination. Accurate identification is crucial for maintaining cable integrity and avoiding errors during installation, repair, or maintenance. Without the correct key, misidentification can lead to significant problems.

Interpreting Color Codes in PDF Charts

Fiber optic cable color code charts, often provided as PDFs, serve as invaluable tools for technicians and engineers. These charts visually represent the color-coding scheme used in a specific cable assembly. Successful interpretation hinges on understanding the chart’s layout and conventions. A typical chart displays a legend correlating colors with fiber numbers, often arranged sequentially. Careful examination is needed to identify the specific color sequence and any additional markings like stripes or tracers, which are crucial for distinguishing fibers beyond the standard 12-color sequence. The chart might also indicate the type of fiber (single-mode or multi-mode) and cable construction (ribbon, loose tube, etc.). Accurate interpretation requires recognizing subtle color variations. The quality of the PDF’s printing and the viewer’s screen calibration can slightly affect color perception. Therefore, it’s crucial to cross-reference the chart with the physical cable whenever possible. PDF charts can be downloaded and saved for easy access during field work. However, always ensure you’re using the correct chart for the specific cable you are working with to prevent misidentification.

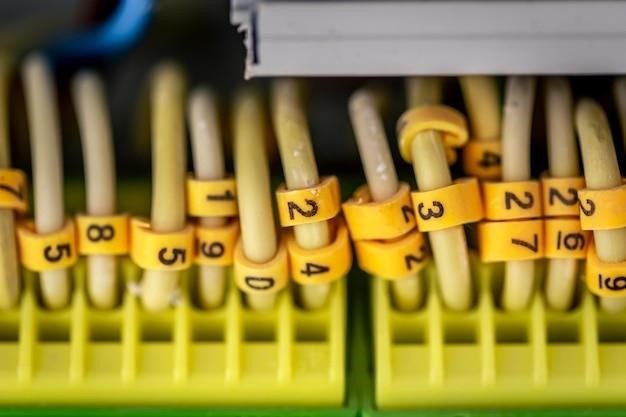

Using Color Codes for Fiber Identification in the Field

Accurate fiber identification in the field relies heavily on understanding and applying color codes. Before commencing any fieldwork, ensure you possess a current, accurate color code chart, ideally a printable PDF version for easy on-site reference. Begin by visually inspecting the cable jacket for any markings indicating the cable’s specifications or manufacturer. This initial check can help pinpoint the appropriate color code chart to use. Once the correct chart is identified, carefully compare the colors on the fibers to those depicted in the chart. Pay close attention to details like stripes or tracers, which are often used to differentiate fibers beyond the basic 12-color sequence. When dealing with high-fiber-count cables, methodical inspection is crucial, possibly requiring the use of magnification tools for precise color differentiation. If discrepancies arise between the physical cable and the chart, double-check the chart’s accuracy and ensure it corresponds to the cable’s specifications. In cases of significant discrepancies, consult the cable manufacturer’s documentation or technical support. Careful, systematic use of color codes in the field minimizes errors and speeds up the fiber identification process, ultimately increasing efficiency and reducing downtime.

Resources for Downloading Fiber Optic Color Code Charts

Numerous online resources provide downloadable fiber optic color code charts in PDF format. Manufacturer websites are excellent starting points; many offer detailed charts specific to their cable products. These often include explanations of their color-coding systems and any manufacturer-specific variations. Industry associations, such as BICSI (Building Industry Consulting Service International) and TIA (Telecommunications Industry Association), frequently publish standards and guidelines, often available as downloadable PDFs. These resources are invaluable for understanding industry-standard color codes and ensuring consistency across projects. Searching online using keywords like “fiber optic color code chart PDF,” “TIA-598-C color code chart,” or “fiber optic cable color code guide” will yield numerous results from various suppliers, consultants, and educational websites. Remember to verify the source’s reliability before using any downloaded chart; reputable sources will usually cite their standards or references. Always cross-reference information from multiple sources to ensure accuracy, especially when working with critical infrastructure. Storing these PDF charts on your computer or mobile device provides readily accessible references for fieldwork.

Common Applications and Industries Using Color Codes

Fiber optic cable color coding finds widespread use across various industries and applications. Telecommunications companies heavily rely on consistent color coding for efficient network installation, maintenance, and troubleshooting. Data centers, with their complex cabling systems, utilize color codes for rapid fiber identification, ensuring seamless connectivity and minimizing downtime. The cable television industry employs color coding for managing extensive networks delivering video and internet services to subscribers. In the military and government sectors, robust and reliable fiber optic networks rely on standardized color coding for security and operational efficiency. Furthermore, industrial automation systems, utilizing fiber optic sensors and communication lines, leverage color coding for simple and quick identification of specific circuits. Healthcare facilities, with their advanced medical equipment relying on fiber optic connections, use color coding for clear identification and maintenance. The energy sector uses color coding in fiber optic networks monitoring power grids and facilitating smart grid technologies. Construction and engineering firms use color-coded fiber optic cables in building and infrastructure projects; Finally, educational institutions and research facilities use color coding in their fiber optic networks supporting advanced research and learning environments.

Troubleshooting and Addressing Color Code Discrepancies

Inconsistent or incorrect fiber optic cable color coding can lead to significant challenges during installation, maintenance, and troubleshooting. Mismatched colors can result in connectivity issues, network failures, and prolonged downtime. To effectively troubleshoot these problems, a systematic approach is crucial. Begin by carefully examining the cable and comparing the observed color codes with the official documentation or provided charts. If discrepancies are found, cross-reference with network diagrams and other relevant documentation. Utilize optical time-domain reflectometers (OTDRs) and other testing equipment to pinpoint the location and nature of the problem. Consult the cable manufacturer’s specifications to confirm adherence to standards and any manufacturer-specific variations. When dealing with older installations, consider the possibility of non-standard or customized color coding schemes, which may require additional investigation. Collaboration between installation teams and network technicians is essential to ensure proper documentation, accurate color coding practices, and efficient problem resolution. For large-scale deployments, implementing a robust quality control system during the installation process helps minimize color code discrepancies from the outset. Thorough documentation and clear communication significantly reduce the likelihood of these issues;

Future Trends in Fiber Optic Cable Color Coding

The field of fiber optic cable color coding is poised for evolution, driven by advancements in technology and the increasing complexity of network infrastructures. One notable trend is the integration of digital identification systems alongside traditional color coding. This might involve embedding RFID tags or using other electronic markers to provide supplementary information and reduce reliance solely on visual identification. The rise of automated fiber identification systems will likely lead to a shift towards standardized digital databases that can readily cross-reference color codes with detailed cable specifications. This digitization could streamline troubleshooting and maintenance procedures. Another area of potential development is the exploration of new color coding schemes optimized for high-fiber-count cables and complex network architectures. This could involve the utilization of more sophisticated color combinations or the implementation of novel marking techniques to improve clarity and minimize ambiguity. Moreover, the development of standardized color coding across different manufacturers is a desirable goal to enhance interoperability and simplify network management. Sustainability is also gaining importance. Future trends may involve the exploration of eco-friendly dyes and marking materials for fiber optic cables, reflecting a broader industry commitment to environmental responsibility. Ultimately, the future of fiber optic cable color coding will likely be shaped by a synergy between traditional methods and innovative digital solutions, ensuring efficient network management in increasingly complex communication systems.